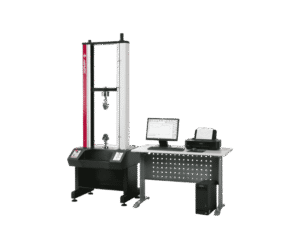

Tensile Testing Machine

Tensile Testing Machine

A precision testing instrument engineered to measure the tensile properties of materials by applying controlled axial force until deformation or failure. This machine quantifies critical mechanical characteristics—such as tensile strength, yield strength, elongation at break, and modulus of elasticity—providing essential data for material validation, quality control, and product development.

A precision testing instrument engineered to measure the tensile properties of materials by applying controlled axial force until deformation or failure. This machine quantifies critical mechanical characteristics—such as tensile strength, yield strength, elongation at break, and modulus of elasticity—providing essential data for material validation, quality control, and product development.

Designed to accommodate diverse materials and industries, the tensile testing machine supports:

- Metals & Alloys: Testing wires, rods, sheets, and fasteners to assess structural integrity under load.

- Plastics & Polymers: Evaluating flexibility, toughness, and resistance to stretching in films, pipes, and molded components.

- Textiles & Fibers: Measuring thread strength, fabric tear resistance, and seam durability for apparel and industrial textiles.

- Rubber & Elastomers: Analyzing elasticity, rebound, and tensile fatigue in gaskets, seals, and flexible materials.

- Composites & Adhesives: Testing bond strength, peel resistance, and layered material performance in aerospace, automotive, and construction applications.

Equipped with high-precision load cells, programmable test speeds, and intuitive software for data logging/analysis, this machine complies with global standards including ASTM D638 (plastics), ISO 527 (polymers), ASTM E8 (metals), and ASTM D5034 (textiles). It is trusted by manufacturers, R&D laboratories, and quality assurance teams to ensure materials meet performance specifications, regulatory requirements, and end-use durability expectations.

Showing the single result