When the 20th China International Rubber Technology Exhibition (RUBBER TECH CHINA) kicked off at Shanghai New International Expo Center, it wasn’t just an event—it was a global rubber industry heartbeat. Bringing together raw material giants, product innovators, and tech wizards, this annual gathering isn’t just about deals; it’s where the future of rubber gets forged.

More Than an Expo: A Launchpad for Innovation

RUBBER TECH CHINA isn’t your average trade show. For years, it’s been the pulse check of the global rubber sector, where 40,000㎡ of exhibition space play host to 1,500+ exhibitors and 20,000+ pros. From raw materials to cutting-edge testing gear, six dedicated zones weave a story of progress—connecting upstream suppliers to downstream pioneers, and turning “what if” into “what’s next” for smarter, greener rubber tech.

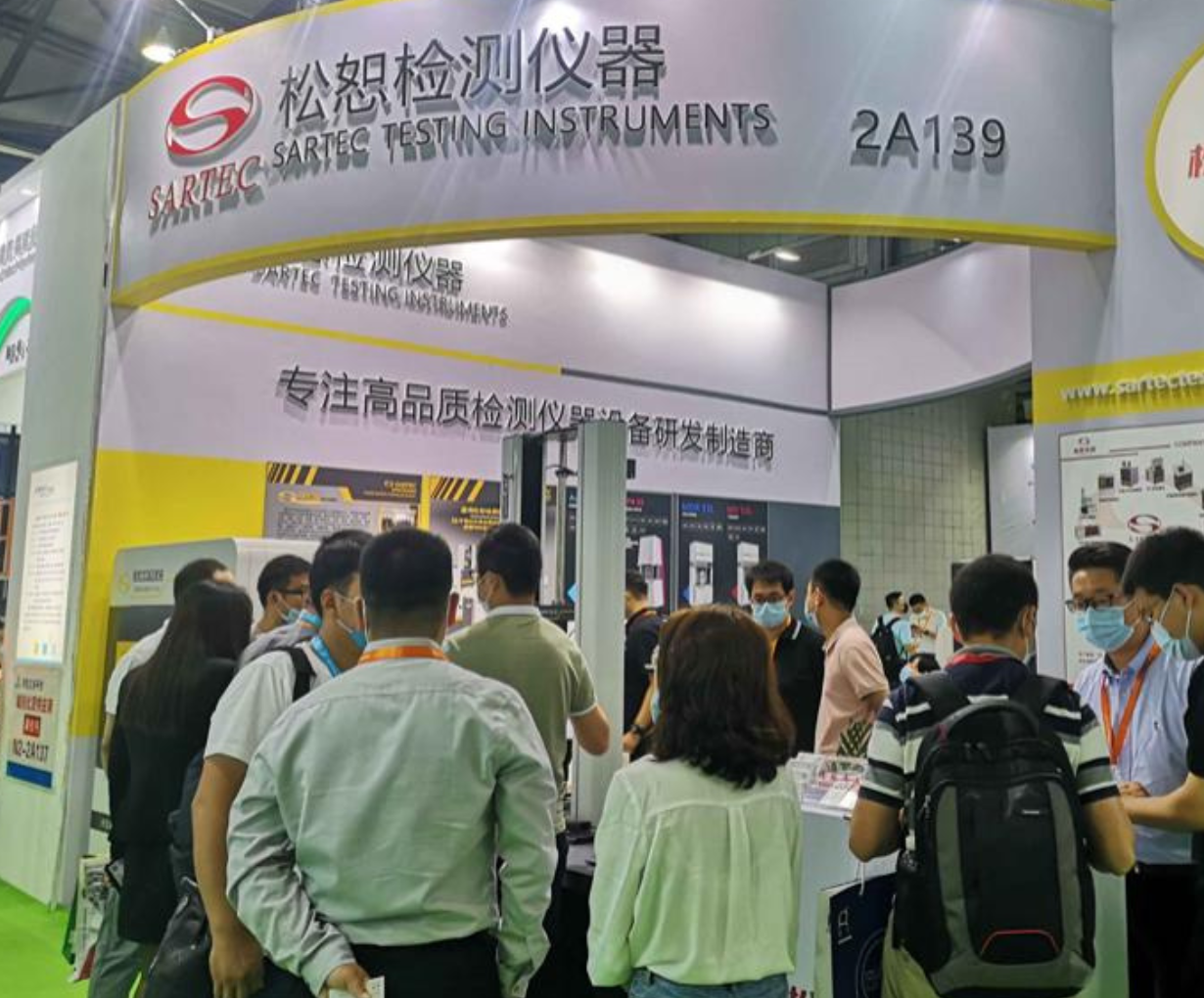

SARTEC’s Booth: Where Precision Meets Passion

SARTEC, a familiar face at the expo, rolled out a booth designed to dazzle—with a lineup of testing tools that don’t just measure quality, but redefine it. Here’s what had the crowd buzzing:

- Ozone Resistance Tester: Think of it as a “toughness simulator.” It cooks up harsh ozone environments (ASTM, ISO, GB standards? Check.) and watches how rubber holds up—with real-time crack tracking. No guesswork, just cold, hard data.

- Low Temperature Brittleness Tester: Rubber’s worst nightmare? Freezing temps. This beast dives to -120°C (thanks to liquid nitrogen) and slams rubber with impacts at 2±0.2m/s. Survival of the fittest, measured to the letter.

- Universal Material Testing Machine: The Swiss Army knife of testers. With a 20KN punch and three smart controls (speed, stress, strain), it puts rubber, plastics, and composites through their paces—no standard left unmet.

- Rubber Impact Resilience Tester: For the “how much can it take?” crowd. It nails CHARPY and IZOD tests with 0.01J precision, proving if rubber parts can handle the chaos of cars, factories, and beyond.

- Rubber Autoadhesion Tester: Sticky situations, solved. It measures how well rubber sticks to itself under perfect temp and pressure—key for tires, seals, and all things that need to stay put.

From Lab Bench to Industry Leader: SARTEC’s Journey

SARTEC didn’t just show up—they grew up with RUBBER TECH CHINA. What started as basic testing gear has morphed into IoT-connected, AI-powered systems. Their team? They’re not just engineers; they’re collaborators—teaming up with universities to cram predictive analytics into software, so tests don’t just report results, they forecast problems.

“SARTEC isn’t in the testing business,” says CEO [Name]. “We’re in the empowerment business. Our tools turn data into decisions—helping customers make better rubber, faster.”

Here’s the Deal: SARTEC Has Your Back

For 20+ years, their mantra’s simple: “Get better. Serve smarter. Grow together.” Need help at 2 a.m.? Their global hotline’s awake. New to the gear? Online training gets you up to speed. On-site techs? They’ll make sure your machines never skip a beat.

What’s Next? The Sky’s the Limit

SARTEC’s already cooking up tools for eco-rubber and nanocomposites. They’re partnering with global standards bodies to write the rulebook for new energy vehicles and aerospace rubber. Because the future doesn’t wait—and neither does SARTEC.

Ready to level up your rubber game? Dive into their gear at www.sartectesting.com, or drop them a line for something custom. The next big thing in rubber? It starts with a test. And SARTEC’s got the tools to make it count.